Electro-Permanent Magnetic Quick Metal Stamping System

For Stamping presses

MBS is suitable for dies of any shape and size, with no modification.Die standardization is not necessary: savings in engineering time and overall cost.

Locating devices are easy to add, scrap holes can be used, bolster extensions can be added. Dies on parallels can be held with the special parallel pole design T-slots in the lower can be added to enable a wide variety of die lifter configurations.

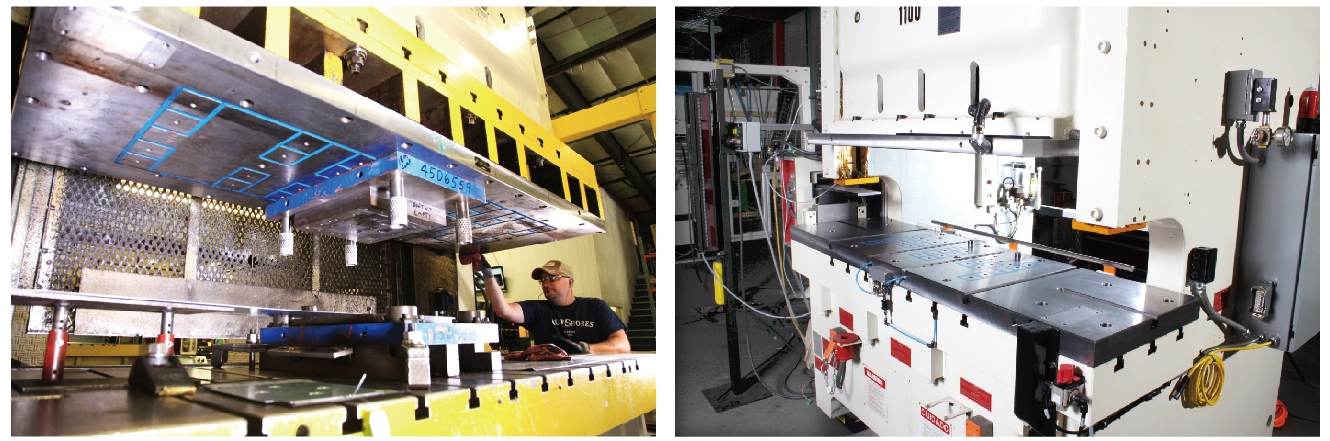

One operator, with no tools, can operate all the Metal Stamping procedure easily and in total safety, outside the presss.

"SAFETY FIRST" SYSTEM

Electro-permanent system does not lose holding force with loss power.

A spring safety key switch must be turned to the enable mode at the same time the mag or de-mag button is pushed eliminating the possibility to mag or de-mag inadvertently.

Bottom dead center interlock prevents de-mag unless press is closed.

Proximity switch puts press into e-stop if a die separates from the magnet and insures the die is flat enough with no air gaps to be properly held.

CSS system checks the internal wiring in the magnet and controller to insure correct system magnetization is achieved.

MSD system checks the magnetic field to insure the die is magnetic and no mechanical damage to the system has occurred during a die change and double checks the aire gap check of the proximity switch.

EASY TO INSTALL

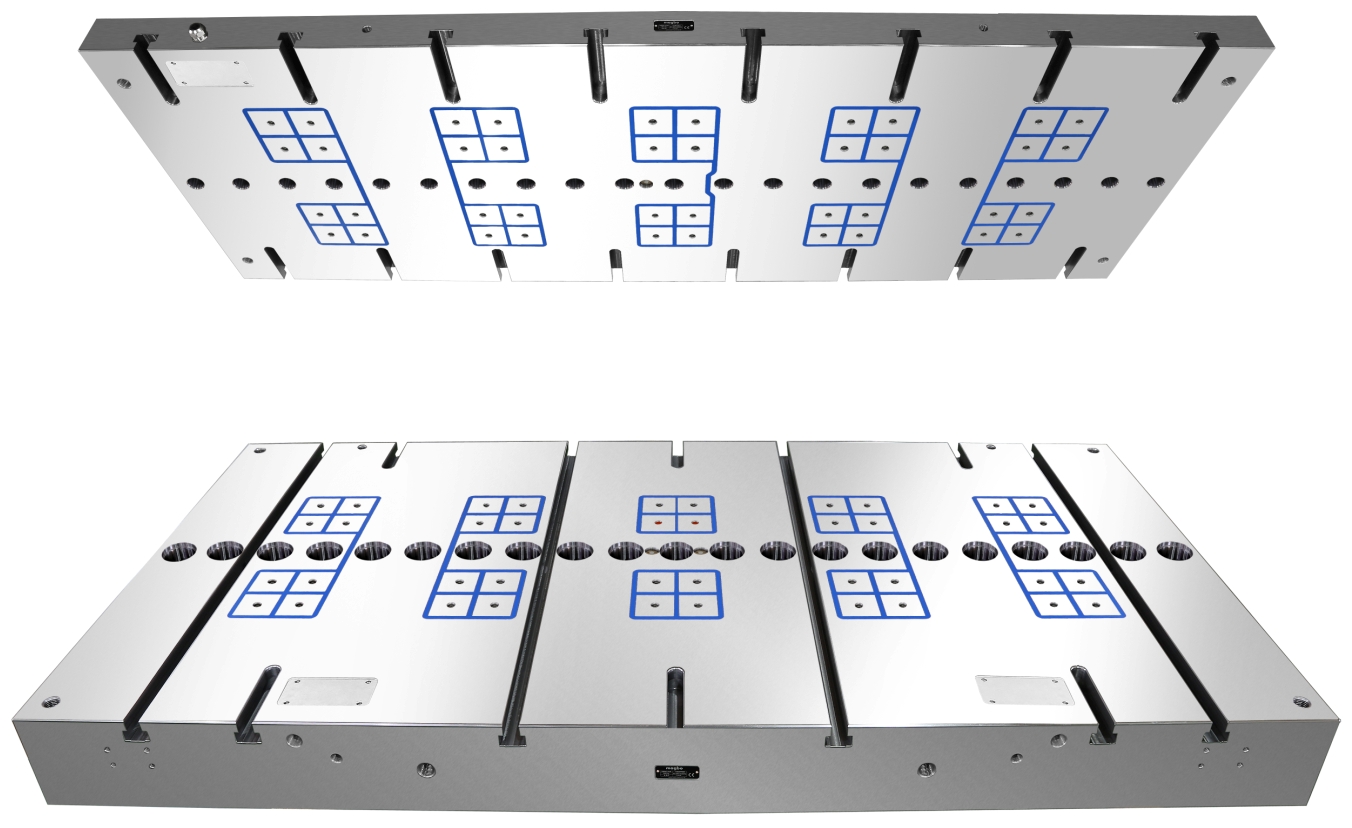

MBS is easy to install: using bolts to mount magnetic plates to existing T-slots or tapped holes.

Its modularity allows adaptability for any need.

No modifications to the press are required. MBS is made to fit your press.

The new reduced thickness of the modules allows to save daylight. Bigger dies can be used in smaller presses.

FAST AND EASY

One operator, with no tools, can operate all the die-clamping easily and in total safety, while staying outside the press.

Load the die, close the press and press the button for the upper, then the lower.

SAFE AND UNIFORM

The MBS technology is not affected by electrical breakdowns; the die will stay in position even without power supply, with the same strength indefinitely. This uniform clamping force allows repeatability and constant quality of the stamping process by eliminating any flexing of die shoe.

DOWNLOAD

SOPH offers the most comprehensive package of magnetic solutions for Workholding, Mold and die clamping, Material handling.

© 2008-2020 Germany - Hamburg | USA - Fenton | China – Haining